|

Anping Jinyuan Metal Co., Ltd.

|

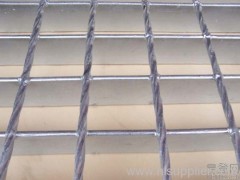

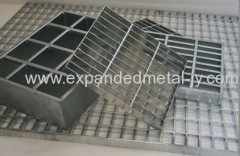

hot dip galvanized steel grating sheets

| Price: | 5.0~17.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

steel grating:high strength, and light structure-Firm mesh welding structure endows it with the characteristics of high load bearing, light structure

Steel grating is the product in accordance with customer's requirements that is lined by load flat steel and horizontal rod alternately in a certain space, welded into primary plate in the high voltage resistance welding machine, then through the deep-processing of such working procedures as cutting, slitting, tapping, bordure, etc.

Its characteristics: high strength, and light structure-Firm mesh welding structure endows it with the characteristics of high load bearing, light structure and convenience for lifting;

handsome appearance and durable-hot galvanizing surface treatment makes it possess good antiseptic power and glossy and handsome surface. Besides, It has good properties of ventilation, lighting, heat elimination, explosion proof and anti skid.

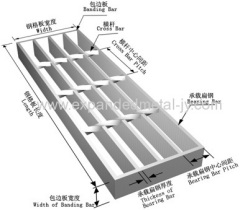

Steel Grating Description:

1) Bearing Bar (Load Bar) Specifications (mm):

The specification of plain type and serrated type bearing bar is 20 x 3 to 100 x 6; The specification of I-section type is 25 x 5 x 3, 32 x 5 x 3, 38 x 5 x 3, 40 x 5 x 3, 50 x 5 x 3, 50 x 7 x 4, 55 x 7 x 4, 60 x 7 x 4, 65 x 7 x 4, 70 x 7 x 4, 75 x 7 x 4, etc.

The specification of plain type and serrated type bearing bar is 20 x 3 to 100 x 6; The specification of I-section type is 25 x 5 x 3, 32 x 5 x 3, 38 x 5 x 3, 40 x 5 x 3, 50 x 5 x 3, 50 x 7 x 4, 55 x 7 x 4, 60 x 7 x 4, 65 x 7 x 4, 70 x 7 x 4, 75 x 7 x 4, etc.

2) Bearing Bar Pitch (center to center):

12.5, 15, 30, 34, 40, 60mm etc, also be according to client's requirement and 30, 40, 60mm are recommended, America standard is available.

12.5, 15, 30, 34, 40, 60mm etc, also be according to client's requirement and 30, 40, 60mm are recommended, America standard is available.

3) Cross Bar Pitch (center to center):

38, 50, 76, 1001 101.6mm etc, also be according to client's requirement and 50, 100mm are recommended, America standard is available.

38, 50, 76, 1001 101.6mm etc, also be according to client's requirement and 50, 100mm are recommended, America standard is available.

4) Material:

Mild Steel (Low Carbon Steel) or Stainless Steel

Mild Steel (Low Carbon Steel) or Stainless Steel

5) Surface Treatment:

Untreated, Painting or Hot dip Galvanizing

Untreated, Painting or Hot dip Galvanizing

6) Steel grating standards:

A) China: YB/T4001-1998

B) USA: ANSI/NAAMM (MBG531-88)

C) UK: BS4592-1987

D) Australia: AS1657-1985

E) Japan: JJS

A) China: YB/T4001-1998

B) USA: ANSI/NAAMM (MBG531-88)

C) UK: BS4592-1987

D) Australia: AS1657-1985

E) Japan: JJS

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Hot Dip Galvanized Steel

Hot Dip Galvanized Steel Coil

Hot Dip Galvanized Steel Strip

Hot Dip Galvanized Wire

Hot Dip Galvanized Coil

Hot Dip Galvanized Iron Wire

More>>

.jpg)

.jpg)

.jpg)